Manufacturing wages are rising quickly in China, so production capacity is beginning to be outsourced to other countries, mainly in Southeast Asia. There will be, however, huge opportunities for African countries to take advantage of this trend, if they are prepared in terms of ensuring sufficient water and power supplies, plus transport infrastructure.

There is no doubt that China’s economic boom over the past 30 years has transformed the face of the international economy. A huge proportion of global manufacturing has transferred to the south and east of the country, triggering the biggest migration in human history, as hundreds of millions of Chinese have moved to provide the manpower.

However, the country has become a victim of its own success. Manufacturing wages in the country have risen by an average of 14% a year over the past five years and now investors are looking to other lower cost centres. The international firms that had outsourced much of their manufacturing capacity to China – and Chinese companies – themselves are looking to cut costs.

At the same time, Beijing is attempting to rebalance the Chinese economy away from its reliance on low-cost manufacturing, towards more highly skilled production, such as industrial engineering and robotics. It is also encouraging greater domestic consumption.

Can Africa benefit?

Other Asian countries are currently benefitting, especially Vietnam, Bangladesh and, in the near future, Myanmar, but there is huge potential for African states to benefit too. The most obvious sectors are textile and clothing production, where wages account for a large proportion of total costs. With the most rapidly growing population of any region, Africa can provide the workforce.

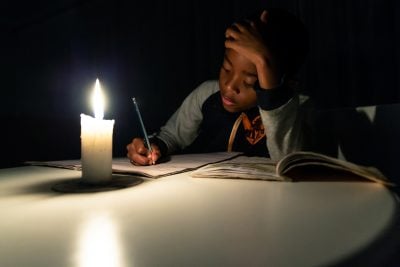

Manufacturing costs are not all about wage levels. The quality of infrastructure is also very important and this is what has let most of Africa down in the past. Power supplies need to be plentiful and reliable, while many producers also consume a lot of water.

Transport infrastructure needs to be able to bring workers and raw materials to the factories and the finished goods to global markets. Such infrastructure has been lacking in many countries but the situation is now changing. Modern, new container terminals are being developed across the region and logistics networks are improving.

Outside South Africa, there is a limited tradition of mass manufacturing in Sub-Saharan Africa. Yet it is easy to forget that China too was a largely agricultural economy until just a generation ago. Sub-Saharan Africa can be transformed in just the same way.

There has already been some modest growth. A report by the Overseas Development Institute earlier this year revealed that sub-Saharan Africa’s manufacturing GDP grew from $73bn in 2005 to $157bn in 2014, representing an average annual increase of 3.5%, above the global average.

Recent initiatives

The government of Ethiopia has stated its ambition to make the most of this trend by creating millions of manufacturing jobs over the next decade. It has drawn up plans for 17 huge industrial parks around the country and the Hawassa Park has already attracted big Chinese and US textile investors.

Ethiopia’s huge investment in dam projects is providing the electricity needed for such projects, with government regulation ensuring that power costs just $0.06/kWh, well below the continental average. In addition, the new Addis Ababa-Djibouti railway is providing the transport capacity to take cargo to the modern new port of Djibouti, which is operated by DP World.

Kenya is holding a Manufacturing Summit & Expo next week in order to attract investment and promote the progress that it has made. The chair of the Kenya Association of Manufacturers, Flora Mutahi, commented: “Supporting such an initiative means that we are ready to dissect issues of local content procurement, sustainable value chains, upgrading our apprenticeships and building capacity for our SMEs to take up opportunities in light manufacturing.”

She added: “In looking at our own capacity we will be able to analyse the gaps that we need to fill for local industry to thrive. Industrialisation, if prioritised, carries the potential to lift other important sectors of the economy as well.”

Neil Ford

Want to continue reading? Subscribe today.

You've read all your free articles for this month! Subscribe now to enjoy full access to our content.

Digital Monthly

£8.00 / month

Receive full unlimited access to our articles, opinions, podcasts and more.

Digital Yearly

£70.00 / year

Our best value offer - save £26 and gain access to all of our digital content for an entire year!

Sign in with Google

Sign in with Google